OVERVIEW

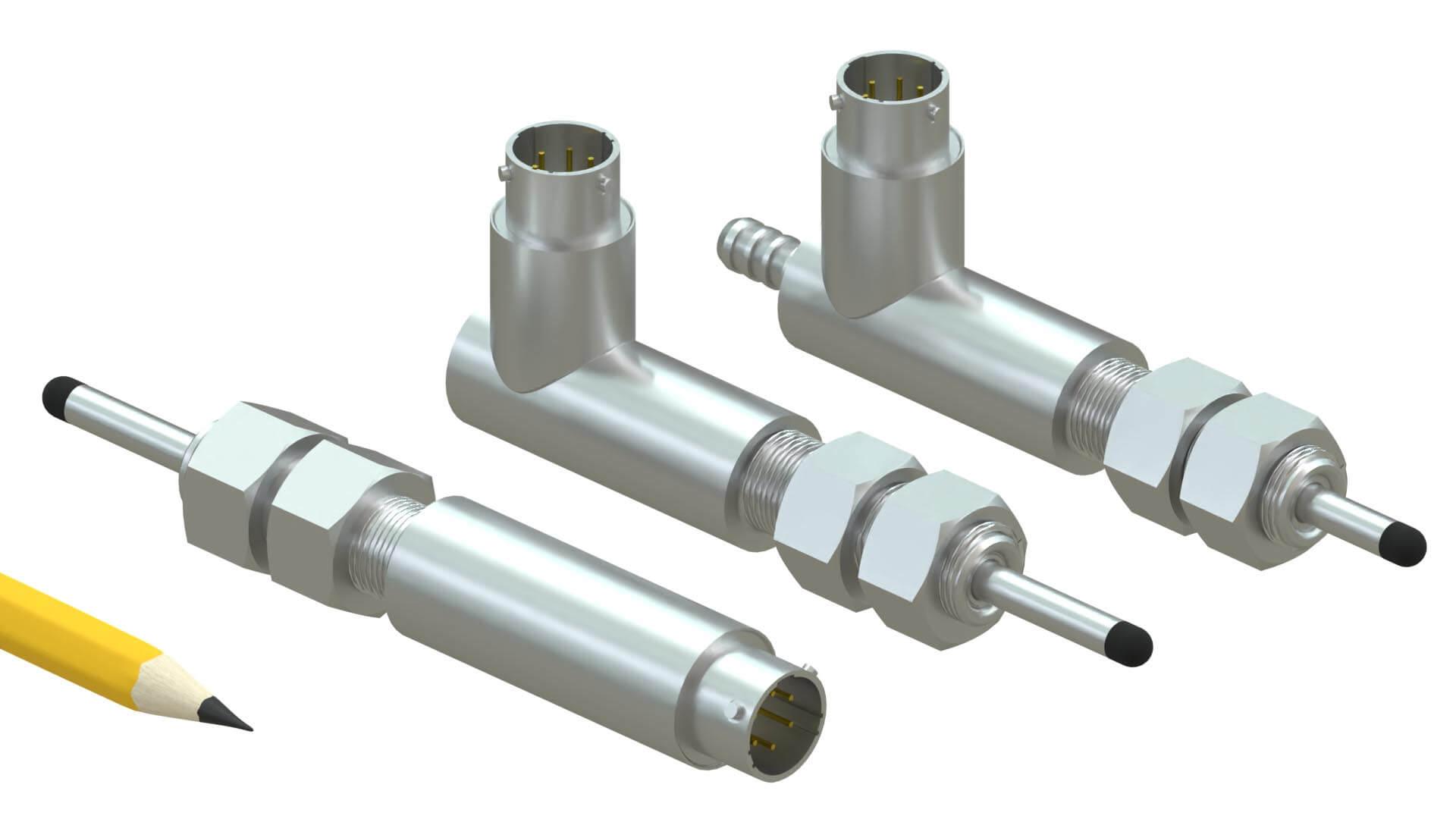

• Spring loaded probe

• Air-extend option available

• 0.750" (19mm) O.D. size body

• Stroke lengths from ± 0.05 to ± 2 inches (±1.2mm to ±50mm)

• Non-Linearity better than ± 0.25% of FS

• Stainless steel housing sealed to IP68

• Applications: Laboratory R&D Materials Testing, Industrial Gauging Test Stands, Factory Automation

MADE IN THE USA

The HGSI GH-750-D/E/I series DC Spring Loaded DC Linear Variable Differential Transformer (LVDT) Position Sensors are used to monitor and track the linear motion or position of a target. These spring-loaded ruggedized sensors are ideal for use in industrial and laboratory applications including automotive R&D, motorsports, industrial, motion control, medical, military and aerospace.

The sensor shaft is spring loaded and guided by a pair of precision sleeve bearings. These hermetically sealed sensors are constructed entirely of stainless steel and are resistant to dust, water, temperature, shock, and vibration. For the air-extend option, the shaft is extended by introduction of a low pressure (10-30 psi), clean, dry air supply, with a regulated flow, through a 1/4 barbed fitting on the end of the unit. With the release of pressure, an internal spring returns the probe to its fully retracted position.

The amplifier electronics are contained within the housing, resulting in no need for an external signal conditioner. The output is pre-calibrated at the factory. GH-750-D

Options:

TECHNICAL SPECIFICATIONS

| GH-750-D | GH-750-E | GH-750-I | |

| Full Scale Output | ±10 VDC | 0 to 10 VDC | 4 to 20 mA. 2-wire loop |

| Input Power | ±15 VDC, ±25 mA | 24 VDC (from 15 to 26 VDC), 25 mA | 24 VDC (from 11 to 28 VDC) |

| Loop Resistance | NA | NA | 50Ω minimum |

Linearity Error: | ≤ ± 0.15% of FSO typical, ± 0.25% maximum |

Null Voltage: | 0.5% of FS |

Repeatability: | 0.01% of FS |

Hysteresis: | 0.01% of FS |

Bandwidth: | 3 Hz (mechanical) |

Operating Temperature: | -20 to +85°C (0 to +185°F) |

Thermal Coefficient: | < -0.02%/°C of FS (< -0.01%/°F of FS) |

Humidity: | 90% RH |

Housing: | Stainless steel |

Contact Tip: | AGD #9 hardened tool steel, chrome plated, #4-48 thread, interchangeable |

Mating Connector: | Amphenol PT06A-10-6S(SR) or equivalent |

Life Expectancy: | > 100 million cycles |

Shock Rating: | 1000g, 11 mS |

Vibration Rating:: | 20 g to 2 kHz |

IP Rating: | IEC IP68 |

DOCUMENTS & DOWNLOADS

VIDEOS

PRODUCT NUMBERS

Product Overview

The GH-750-D/E/I Series of Spring-Loaded DC LVDT Position Sensors from Harold G. Schaevitz Industries offer robust, linear displacement sensing for industrial gauging, and research environments. Designed with a rugged stainless steel housing, and integrated electronics, these sensors provide long-term durability and accurate position feedback across a wide range of applications.

The built-in spring-loaded shaft ensures consistent contact with the target surface, making the GH-750 series ideal for gauging, surface tracking, and dimensional measurements. Whether for factory automation, material testing, or mobile machinery, these sensors deliver high-resolution, repeatable measurements in harsh conditions.

Key Features

DC-Operated LVDT Sensor with integrated electronics (no external signal conditioner required)

Spring-loaded probe ensures consistent measurement contact

Heavy-duty 0.750" (19 mm) diameter stainless steel housing

Available in multiple output types: Voltage (D/E) or 4–20 mA current loop (I series)

Stroke lengths from ±0.050 to ±2.00 inches (±1.3 mm to ±50 mm)

Sealed to IP68 for full environmental protection

Non-linearity better than ±0.25% of full scale

Made in the USA with industrial-grade materials

Built for Precision in Demanding Environments

The GH-750-D/E/I series is specifically designed for applications where accuracy, durability, and ease of integration are paramount. These spring-loaded sensors incorporate a precision return spring to maintain constant surface contact, and internal sleeve bearings that guide the probe shaft with minimal friction or play.

Each unit is hermetically sealed and resistant to dust, water, shock, and vibration, ensuring years of trouble-free operation in even the most aggressive operating environments.

Output Options

The GH-750 series includes multiple output variants to meet your system’s requirements:

GH-750-D: ±10 VDC output

GH-750-E: 0–10 VDC output

GH-750-I: 4–20 mA current loop output

All versions operate with standard DC input voltages and offer stable, low-noise output for direct connection to control systems or data acquisition equipment.

Applications

Industrial Gauging Systems

Dimensional inspection and in-process precision thickness measurement

Roll stand and caliper positioning

Contact-type scanning of manufactured components

Factory Automation

Closed-loop control in automated machinery

Position verification and sorting

Real-time process monitoring

R&D and Test Laboratories

Materials and component testing setups

Displacement and deflection tracking

Life cycle and fatigue testing

Rugged Design and Environmental Sealing

The GH-750-D/E/I’s stainless steel housing and sealed construction (rated to IP68) protect the sensor from the environment. These features make it suitable for submersion, outdoor exposure, or environments where dust, fluids, and debris are common.

The epoxy-potted electronics provide additional resistance to shock, vibration, and thermal cycling, ensuring the sensor performs consistently in the toughest conditions.

Easy Integration

These sensors are plug-and-play compatible with most industrial systems:

Built-in electronics eliminate the need for external signal conditioners

Standard output formats ensure compatibility with PLCs, controllers, and DAQ modules

Simplified mounting with a smooth cylindrical body and threaded front nose

Field-proven reliability for reduced maintenance and long service life

Why Choose the GH-750-D/E/I Series?

Reliable, spring-loaded contact design

Fully integrated signal conditioning simplifies installation

Wide selection of stroke ranges and output formats

Suitable for continuous industrial use in harsh environments

Backed by U.S.-based manufacturing and support

Conclusion

The GH-750-D/E/I Series DC Spring-Loaded LVDT Position Sensors provide an ideal solution for demanding linear measurement applications requiring high precision, ruggedness, and ease of integration. Whether you're outfitting a quality control station, automating a production process, or monitoring motion in harsh field conditions, this sensor series delivers the performance and reliability needed to succeed.

Have questions about the best model for your application?

Contact our application engineers today for expert guidance and customized recommendations.