OVERVIEW

• Cybersecurity lock to prevent tampering

• Smart calibration by front panel push buttons

• Differential input for superior noise immunity

• Color-coded screw terminal plugs

• Auto-mastering

• Hot swapability

• Shorted, disconnected, or open primary

• Shorted, grounded, disconnected, or open secondaries

• Output voltage shorts or current loop opens

• Errors during installation and setup

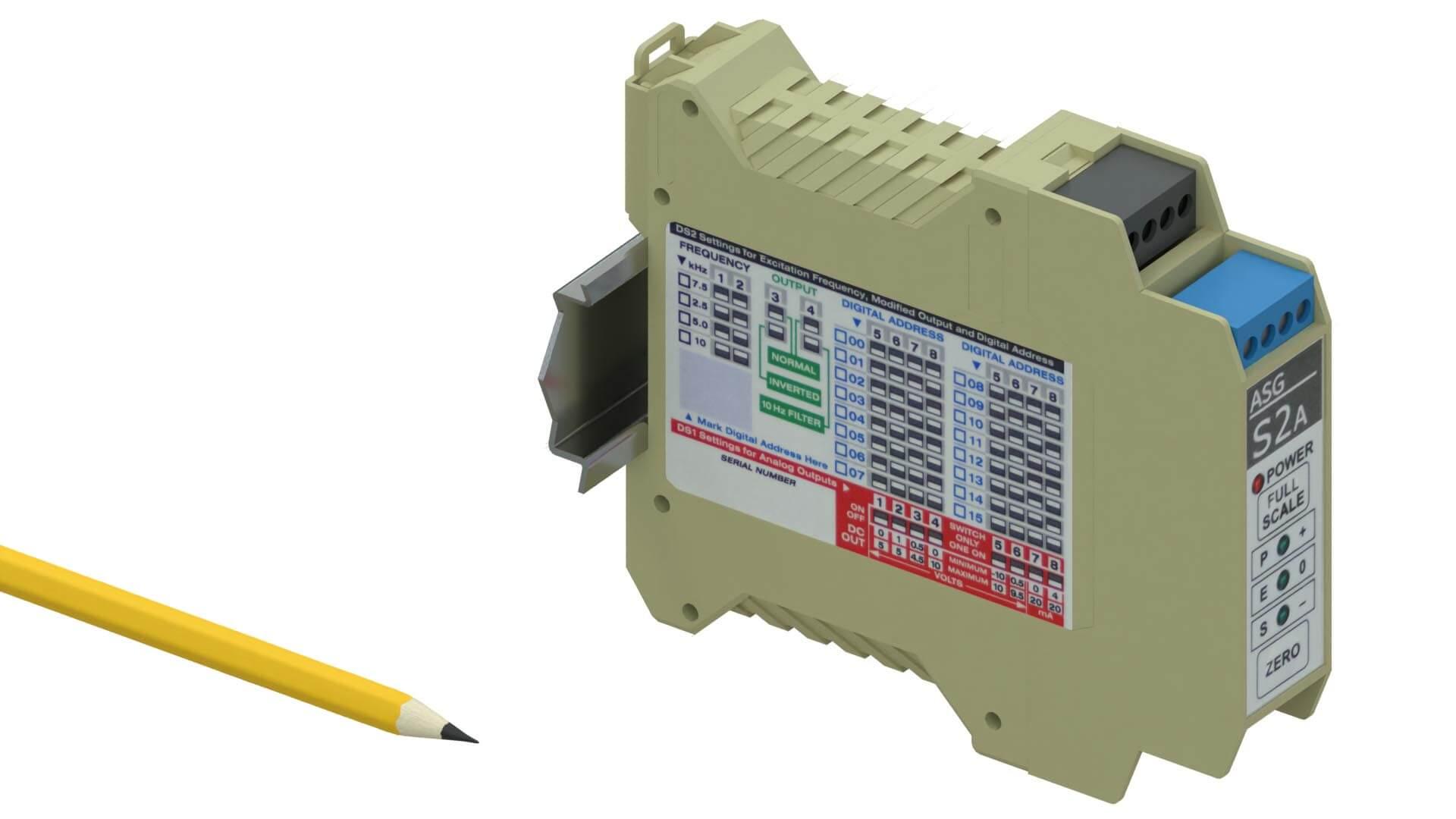

Alliance Sensors Group's model S2A DIN-rail-mounting LVDT signal conditioner is designed specifically for the power generation industry. It offers comprehensive diagnostics for sensor or wiring failure, real time recalibration of the Full Span and Zero outputs, enhanced ground loop noise rejection, and backward compatibility to legacy S1A signal conditioners. Utilizing front panel push buttons for easy calibration, the S2A is engineered to work with the widest range of LVDT, RVDT, and inductive half-bridge LVRT sensors by providing four excitation frequencies that will operate most AC-LVDTs over a 50 to 5,000 mVrms range of sensor output. S2A modules offer a choice of 8 analog ouptuts and half-duplex RS-485 digital communications to facilitate remote setup and for saving a module's setup parameters to hot swap them with another module.

The RS-485 port also funstions with a setup GUI available and the S2A manual are available below.

TECHNICAL SPECIFICATIONS

| Operating Power: | +15 to +30 V DC (+24 V nominal), 80 mA max. at 24 V DC; +15 V DC and -15 V DC needed for ±10 V DC bipolar output |

| Analog DC Outputs: | 0 - 5 V, 1 - 5 V, 0.5 - 4.5 V, 0.5 - 9.5 V, 0 -10 V, -10 to +10 V, 0 - 20 mA sourcing (3-wire), 4 - 20 mA sourcing (3-wire) |

| Loop Resistance: | 850 Ohms maximum with 24 V DC supply |

| -3 dB Response: | 10% (minimum) of excitation frequency (normal setting); 10 Hz (default) user adjustable (low noise setting) |

| Noise and Ripple: | ≤1 mVrms (voltage output); ≤2 μArms (current loop output) |

| Output Non-Linearity: | ≤±0.025% of Full Span Output (FSO) |

| Operating Temperature: | -20 to 75 C |

| Temperature Coefficient: | ±0.002% of FSO/C (combined zero and span shift) |

| Excitation Frequencies: | 1 kHz, 3 kHz, 5 kHz, 10 kHz (nominal) |

| LVDT Output Range: | 50 mVrms to 5000 mVrms at LVDT’s full scale position |

| Excitation Voltage: | 3.0 Vrms (nominal) push-pull drive (factory default) 4.5 Vrms (nominal) push-pull drive (via jumper change) 1.5 Vrms (nominal) single ended drive (for low impedance primary) |

| Auto-Master Syncing: | Master output couples up to fifteen slave units; if the master fails, a new master is automatically generated for fail-safe excitation |

| Fault Detection: | Open LVDT windings, shorted or grounded LVDT connections, LVDT cable disconnected, voltage output shorted or current loop open |

| Failure Indications: | Flashing LED's; analog output driven out of range; open-collector switch, user settable to NO (default) or NC |

| Null Detection: | Front panel LEDs; +/-3V DC null output signal |

| Zero Set: | Front panel push button or RS-485 command |

| Full Scale Set: | Front panel push button or RS-485 command |

| Digital Interface: | RS-485 2-wire multi-drop network, 16 addresses |

| Cybersecurity Lock: | User enabled |

DOCUMENTS & DOWNLOADS

VIDEOS

PRODUCT NUMBERS

S2A LVDT Signal Conditioner: Advanced Industrial Position Measurement Processing

Product Description

The Alliance Sensors Group S2A LVDT Signal Conditioner represents the state of the art in signal processing technology for industrial position measurement applications. Designed specifically for the power generation industry but versatile enough for numerous industrial applications, this DIN-rail-mounting module delivers superior performance and reliability through comprehensive diagnostics, enhanced noise immunity, and simplified calibration procedures. The S2A supports a wide range of LVDT, RVDT, and inductive half-bridge LVRT sensors, offering exceptional flexibility for diverse measurement systems. With its cybersecurity features, smart calibration capabilities, and multiple analog output options, the S2A provides a robust solution for critical position feedback in demanding industrial environments such as power generation applications.

Advanced Features

Comprehensive Diagnostics

The S2A incorporates extensive fault detection capabilities that continuously monitor sensor integrity and connection status. The system immediately identifies and flags conditions such as open LVDT windings, shorted or grounded LVDT connections, disconnected cables, shorted voltage outputs, or open current loops. These diagnostic capabilities are presented through multiple channels including flashing LEDs, out-of-range analog outputs, and configurable open-collector switches that can be integrated with alarm systems. This comprehensive health monitoring significantly reduces troubleshooting time and prevents erroneous measurements that could compromise system performance or safety.

Cybersecurity Protection

In recognition of the increasing importance of industrial control system security, the S2A incorporates a user-enabled cybersecurity lock that prevents unauthorized parameter modifications and can only be modified by physical interaction with the front panel. This feature is particularly valuable in critical infrastructure applications such as power generation, where maintaining the integrity of measurement systems is essential. The security lock ensures that calibration settings and configuration parameters remain protected against both accidental changes and deliberate tampering, enhancing overall system reliability and compliance with industrial cybersecurity protocols.

Simplified Calibration

The S2A features intuitive front-panel push buttons that streamline the calibration process, eliminating the need for specialized tools or complex procedures. Real-time recalibration of Full Span and Zero outputs can be performed while the system is online, minimizing downtime and ensuring continuous operation. For installations where physical access is limited, these calibration procedures can also be executed remotely via RS-485 commands, providing excellent flexibility for maintaining measurement accuracy across distributed systems or in challenging access locations.

Connectivity Options

Versatile Output Configuration

The S2A offers exceptional flexibility with eight selectable analog output formats, accommodating virtually any control system interface requirement. Voltage output options include 0-5V, 1-5V, 0.5-4.5V, 0.5-9.5V, 0-10V, and -10 to +10V, while current loop options include 0-20mA and 4-20mA sourcing (3-wire). This extensive selection eliminates the need for additional signal conversion components in most applications, simplifying system architecture and reducing potential points of failure. The outputs maintain excellent signal integrity with minimal noise and ripple (≤1mVrms for voltage outputs, ≤2μArms for current loop outputs).

Digital Communications

In addition to conventional analog outputs, the S2A provides half-duplex RS-485 digital communications capability, supporting multi-drop networks with 16 addressable units. This digital interface facilitates remote setup, monitoring, and parameter management, enabling integration with computerized control systems and maintenance platforms. A dedicated setup GUI is available for streamlined configuration and diagnostics, simplifying commissioning and maintenance operations. The digital interface also supports parameter backup and restoration, allowing rapid replacement of modules while maintaining exact configuration settings.

Sensor Compatibility

Universal LVDT Interface

The S2A is engineered to work with an exceptionally wide range of LVDT, RVDT, and inductive half-bridge LVRT sensors, accommodating output signals from 50mVrms to 5000mVrms at the sensor's full-scale position. This universal compatibility is achieved through four selectable excitation frequencies (1kHz, 3kHz, 5kHz, and 10kHz nominal) and multiple excitation voltage options, including 3.0Vrms push-pull drive (factory default), 4.5Vrms push-pull drive (via jumper), or 1.5Vrms single-ended drive for low impedance primaries. This extensive range of configuration options ensures optimal performance with virtually any inductive position sensor, regardless of manufacturer or specific design characteristics.

Enhanced Noise Immunity

Industrial environments often present significant electromagnetic interference challenges that can compromise measurement accuracy. The S2A addresses these challenges through differential input design that delivers superior common-mode noise rejection, particularly effective against ground loop noise. This noise immunity is further enhanced by user-selectable filtering options, including a low-noise setting with a 10Hz (default) adjustable response and a normal setting that scales with the excitation frequency. These features ensure reliable, accurate measurements even in electrically noisy industrial environments such as power plants, steel mills, or heavy manufacturing facilities.

System Integration

Hot-Swap Capability

The S2A supports hot-swappable operation, allowing module replacement without powering down the system or disrupting other measurement channels. This capability is enhanced by the module's parameter memory, which can be backed up and restored to ensure consistent configuration during replacements. For applications where continuous operation is critical, this feature minimizes downtime and simplifies maintenance procedures, contributing to overall system availability and reliability.

Auto-Master Synchronization

For multi-channel measurement systems, the S2A provides an auto-master synchronization feature that couples up to fifteen slave units to a single master excitation source. This synchronization eliminates potential interference between adjacent channels and ensures consistent timing across the measurement system. The architecture incorporates fail-safe operation—if the master unit fails, a new master is automatically generated to maintain system functionality. This robust approach to multi-channel synchronization is particularly valuable in applications requiring multiple coordinated measurements, such as turbine valve positioning or multi-point structural monitoring.

Installation Convenience

The S2A's physical design prioritizes installation simplicity with DIN-rail mounting for easy integration into standard industrial enclosures. Color-coded screw terminal plugs facilitate correct wiring and allow pre-wiring of harnesses before module installation. The comprehensive manual and available setup GUI further streamline the commissioning process, reducing installation time and potential configuration errors. For organizations transitioning from legacy systems, the S2A maintains backward compatibility with the legacy S1A signal conditioners, simplifying migration to the enhanced capabilities of the newer platform.

Performance Specifications

The S2A delivers exceptional measurement performance with output non-linearity of ≤±0.025% of Full Span Output (FSO) and an excellent temperature coefficient of ±0.002% of FSO/°C (combined zero and span shift). Operating reliably across temperatures from -20°C to 75°C, the module maintains consistent performance in various industrial environments. Power requirements are straightforward, with operation from +15 to +30V DC (+24V nominal) at 80mA maximum, with additional requirements of +15V DC and -15V DC only for ±10V DC bipolar output applications.

Application Areas

Power Generation

As a product specifically designed for the power generation industry, the S2A excels in applications such as turbine valve positioning, generator alignment monitoring, and control rod position feedback. Its robust diagnostics, cybersecurity features, and reliable performance make it an ideal solution for these critical measurement applications where accuracy and reliability directly impact operational safety and efficiency.

Process Industries

In process industries such as chemical manufacturing, petroleum refining, and water treatment, the S2A provides precise position feedback for control valves, gate positions, and mechanical linkages. The module's comprehensive diagnostics and fail-safe design contribute to process reliability and safety, while its flexibility accommodates diverse sensor types commonly found throughout these applications.

Heavy Manufacturing

For heavy manufacturing applications including steel production, paper mills, and mining operations, the S2A offers the rugged performance and noise immunity required in these challenging environments. Its ability to operate reliably despite electrical noise, temperature variations, and mechanical vibration ensures consistent measurement accuracy for critical position feedback applications such as roll gap measurement, material handling positions, and press displacement monitoring.

The Alliance Sensors Group S2A LVDT Signal Conditioner combines advanced signal processing capabilities with robust industrial design to deliver exceptional performance and reliability for position measurement applications. Its comprehensive feature set, extensive compatibility, and thoughtful integration capabilities make it an ideal solution for critical measurement systems across a wide range of industries.