OVERVIEW

• Spring loaded probe

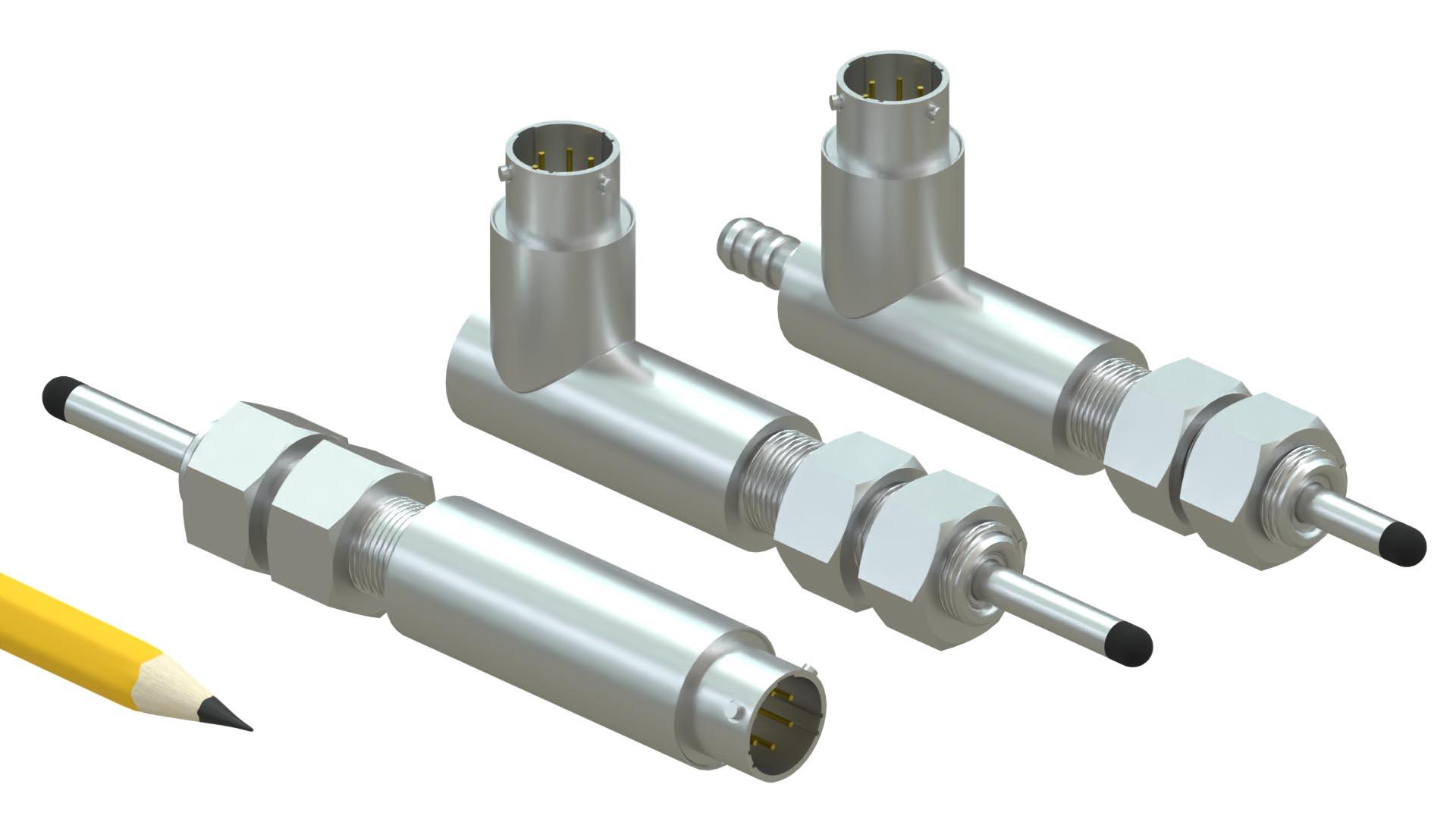

• Air-extend option available

• 0.750" (19mm) O.D. size body

• Stroke lengths from ± 0.05 to ± 2 inches (±1.2mm to ±50mm)

• Non-Linearity better than ± 0.25% of FS

• Stainless steel housing sealed to IP68

• Applications: Laboratory R&D Materials Testing, Industrial Gauging Test Stands, Factory Automation

MADE IN THE USA

The HGSI GH-750-A series AC Spring Loaded Linear Variable Differential Transformer (LVDT) Position Sensors are used to monitor

and track the linear motion or position of a target. These spring-loaded ruggedized sensors are ideal for use in industrial and laboratory

applications including automotive R&D, motorsports, industrial, motion control, medical, military and aerospace.

The sensor shaft is spring loaded and guided by a pair of precision sleeve bearings. These hermetically sealed sensors are constructed

entirely of stainless steel and are resistant to dust, water, temperature, shock, and vibration. For the air-extend option, the shaft is

extended by introduction of a low pressure (10-30 psi), clean, dry air supply, with a regulated flow, through a 1/4 barbed fitting on the

end of the unit. With the release of pressure, an internal spring returns the probe to its fully retracted position.

The GH-750-A series will operate with most any conventional differential input AC LVDT signal conditioner, but operation with

ratiometric signal conditioning is not recommended. HGSI offers a full line of compatible AC LVDT signal conditioners.

Options:

TECHNICAL SPECIFICATIONS

Input Voltage: | 3 Vrms (nominal) |

Input Frequency: | 400 Hz to 10 kHz |

Linearity Error: | ≤ ± 0.15% of FSO typical, ± 0.25% maximum |

Null Voltage: | 0.5% of FS |

Repeatability: | 0.01% of FS |

Hysteresis: | 0.01% of FS |

Bandwidth: | 3 Hz (mechanical) |

Operating Temperature: | Standard Version: -54 to +135°C (-65 to +275°F) |

Thermal Coefficient: | < -0.02%/°C of FS (< -0.01%/°F of FS) |

Humidity: | 90% RH |

Housing: | Stainless steel |

Contact Tip: | AGD #9 hardened tool steel, chrome plated, #4-48 thread, interchangeable |

Mating Connector: | Amphenol PT06A-10-6S(SR) or equivalent |

Life Expectancy: | > 100 million cycles |

Shock Rating: | 1000g, 11 mS |

Vibration Rating:: | 20 g to 2 kHz |

IP Rating: | IEC IP68 |

DOCUMENTS & DOWNLOADS

VIDEOS

PRODUCT NUMBERS

Product Overview

The GH-750-A Series Spring-Loaded AC LVDT from Harold G. Schaevitz Industries delivers industrial-strength performance for demanding measurement applications. Built with a rugged stainless steel housing and available with an optional air-extend feature, this sensor offers reliable, high-accuracy linear displacement measurement in challenging environments.

With stroke lengths ranging from ±0.05 to ±2.0 inches (±1.2 mm to ±50 mm), a 0.750" (19 mm) diameter body, and a non-linearity of better than ±0.25% of full scale, the GH-750-A series excels in high-precision gauging, dimensional testing, and factory automation. Its sealed design, built to IP68, ensures long-term durability in wet, dusty, and high-shock environments.

Precision Performance with Rugged Design

The GH-750-A combines precision measurement capabilities with robust mechanical construction. It uses a spring-loaded plunger mechanism, guided by dual precision sleeve bearings, to maintain smooth axial motion and minimize side-loading effects. This configuration is ideal for high-cycle testing or repetitive contact measurement tasks.

The sensor's hermetically sealed stainless steel housing is designed for superior protection against moisture, dirt, and contaminants, while also withstanding significant mechanical shock and vibration.

Optional Air-Extend Feature

The air-extend configuration adds a powerful automation capability to the GH-750-A series. When connected to a regulated clean, dry air supply (10–30 psi), the sensor’s probe extends automatically via pneumatic force through a 1/4” barbed fitting on the sensor body. Once the pressure is released, an internal spring returns the shaft to its retracted position.

This feature is especially valuable in environments where sensor contact needs to be precisely controlled or synchronized with machine operations.

Applications

Laboratory R&D and Materials Testing

Designed for use in dimensional metrology, materials deformation testing, and displacement feedback in automated test systems, the GH-750-A excels in lab environments requiring repeatable, contact-based measurements.

Industrial Gauging Systems

Perfect for high-cycle industrial gauging stands and in-line quality control systems, the GH-750-A delivers rugged, long-life performance and precise displacement tracking in factory environments.

Factory Automation and Process Control

Whether used for real-time position feedback, alignment monitoring, or part presence detection, the GH-750-A integrates seamlessly into process control systems where contact measurement is required.

Automotive and Aerospace

In automotive R&D and aerospace component testing, the sensor’s durability and precision are ideal for applications like suspension testing, parts qualification, and vibration response analysis.

System Integration and Compatibility

The GH-750-A is designed to operate with most standard differential-input AC LVDT signal conditioners. It is not recommended for use with ratiometric signal conditioning systems. Harold G. Schaevitz Industries offers a full line of compatible signal conditioners tailored to meet your application requirements—contact our engineering team for recommendations.

Built for Harsh Environments

IP68 sealed for protection against dust and submersion in water

Stainless steel construction for corrosion and impact resistance

Internal components designed to withstand extreme temperature swings, mechanical shock, and vibration

Suitable for both indoor and outdoor operation, including in automated or mobile systems

Why Choose the GH-750-A Series?

Precision contact measurement with built-in spring-loaded mechanism

Pneumatic extension option

Compact and durable for industrial and lab settings

Easy integration with common AC LVDT signal conditioners

Made in the USA with support from experienced application engineers