OVERVIEW

Specifically Designed and Engineered for Applications in Power Generating Steam Turbine Control Systems

- Guided Core design

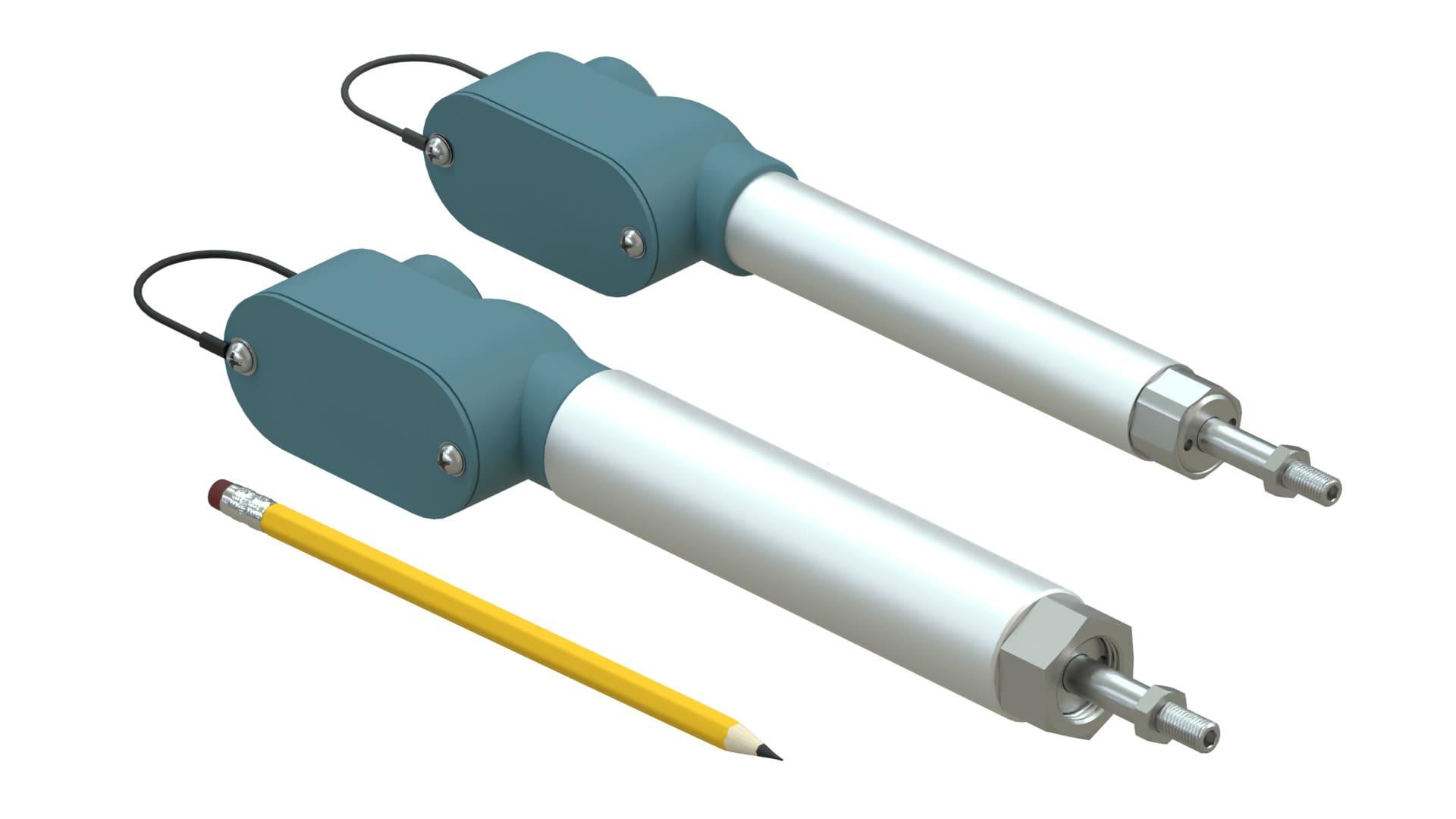

- 1.05" (27mm) O.D. or 1.32" (34mm) size body

- Stroke lengths from 3" to 15"

- Stainless steel housing sealed to IP62

Alliance Sensors PG Series LVDT linear position sensors are designed and engineered specifically for steam turbine valve position control system applications in electric power plants. Many of the features incorporated in the design were actually requested by power generation controls engineers. PG sensor models include the PGHD Heavy Duty LVDT and the PGSD Super Duty LVDT. Both PG versions are available on special order as mild radiation resistant for operation in BWR nuclear power plants.

The PG Series LVDT linear sensors are heavy duty, from the wire connection terminal block inside an IP-68 sealed heavy wall housing to the 3/8 inch outside diameter core rod in which the LVDT core is encased so that it can never vibrate loose or break off. A pair of double contact shaft seals for the core rod keep dirt and water out of the sensor’s bore. An in-line ball joint coupling on the core connecting rod to take up minor

installation misalignment is optionally available, along with other installation hardware such as hold-down clamps, threaded core extension rods, swivel rod eye ends, and mounting flanges. Electrical connections utilize a screw-clamp terminal block for 24 to 14 AWG wires that feed through a 3/4 inch conduit hub outfitted with a 1/2 inch conduit adapter. User-installable connectors are available.

TECHNICAL SPECIFICATIONS

| Excitation Frequency: | 3 kHz nominal |

| Excitation Voltage: | 3 V ACrms nominal |

| Full Scale Output: | 0.9 V ACrms output (nom.) from differentially connected (S1-S2) secondaries with 3 Vrms excitation; sum of secondaries output is constant over range for ratiometric (S1-S2)/(S1+S2) operation |

| Linearity Error: | ±0.3% of FSO nominal, ±0.5% of FSO max |

| Operating Temperature: | -40 to 175 C (-40 to 350 ˚F) |

| Temperature Coefficient: | ≤ 0.025% FSO/degree C |

| Shock: | 1000 g, 11 msec |

| Vibration: | 5-20 Hz, 0.5 inch p-p; 20-2000 Hz, 4.2 g p-p |

DOCUMENTS & DOWNLOADS

VIDEOS

PRODUCT NUMBERS

Purpose-Built for Steam Turbine Valve Position Control

The PGHD (Heavy Duty) and PGSD (Super Duty) Series LVDT Position Sensors from Alliance Sensors Group are rugged, high-reliability linear position sensors specifically designed for steam turbine valve position feedback in power generation control systems. Engineered with direct input from power plant control engineers, these sensors deliver the precision, strength, and resilience required in critical valve monitoring and control applications.

Key Features

Guided-core design for mechanical stability and vibration resistance

Robust housing: Choose from 1.05" (27 mm) or 1.32" (34 mm) diameter stainless steel bodies

Stroke lengths available from 3 to 16 inches

IP62 sealing for protection in industrial environments

Double contact shaft seals prevent ingress of dust, moisture, and contaminants

Core rod with enclosed core eliminates risk of detachment or vibration fatigue

Threaded conduit hub with ¾" entry and ½" adapter for versatile wiring setups

Optional mild radiation-resistant versions available for BWR nuclear applications

Screw-clamp terminal block supports 24 to 14 AWG wires

Made in the USA

Engineered for Power Generation

The PG Series LVDTs were purpose-built for the demanding steam turbine valve control systems found in conventional fossil fuel, hydroelectric, and nuclear power plants. They provide reliable real-time position feedback for:

Interceptor valves

Throttle valves

Governor valves

Stop valves

Bypass valves

These sensors help ensure the precise operation of control loops critical to turbine efficiency, response time, and safety.

Heavy-Duty Construction

Both the PGHD and PGSD models are designed for maximum resilience and stability in power plant conditions. The sensor core is encased in a rugged ⅜-inch diameter extension rod that cannot break off or vibrate loose, ensuring long-term reliability in high-vibration environments. The robust housing and double shaft seals protect against dust, water, oil, and other contaminants found in turbine decks and valve galleries.

Designed for Power Gen Applications

The PG Series includes features to simplify installation and alignment:

Optional in-line ball joint coupling accommodates slight misalignment

Available accessories: hold-down clamps, rod eye ends, flanges, and extension rods

Terminal block connections for easy field wiring

Flexible conduit compatibility with user-installable connectors

This flexibility minimizes downtime and simplifies sensor replacement during maintenance or system upgrades.

Reliable Performance for Critical Systems

Alliance Sensors Group has worked closely with power generation engineers to ensure the PG Series meets the highest standards for:

Stability in high-vibration and thermal cycling environments

Durability under extended continuous operation

Accuracy in valve positioning applications under dynamic load conditions

By using guided-core AC LVDT technology, the PG Series eliminates mechanical contact wear points and delivers high resolution, repeatable measurements over millions of cycles.

Mild Radiation-Resistant Option

For boiling water reactor (BWR) nuclear power applications, both the PGHD and PGSD models can be special-ordered with radiation-tolerant construction, making them suitable for mounting in containment zones requiring additional environmental resistance.

Why Choose the PGHD / PGSD Series?

The PGHD and PGSD Series AC LVDT sensors represent the pinnacle of heavy-duty linear position sensing for the power generation sector. Built for demanding environments, engineered with input from turbine control professionals, and backed by Alliance Sensors Group’s commitment to quality, these sensors deliver the long-term performance and reliability essential for modern energy systems.

Designed specifically for steam turbine valve control applications

Proven in fossil, hydro, and nuclear power plants

Exceptional mechanical strength and vibration resistance

Rugged stainless steel construction and guided-core design

Flexible installation options with industry-standard wiring compatibility

Made in the USA with power plant applications in mind

Need help selecting the right configuration for your turbine control application? Contact our technical team today for support, specifications, and custom options tailored to your installation.