OVERVIEW

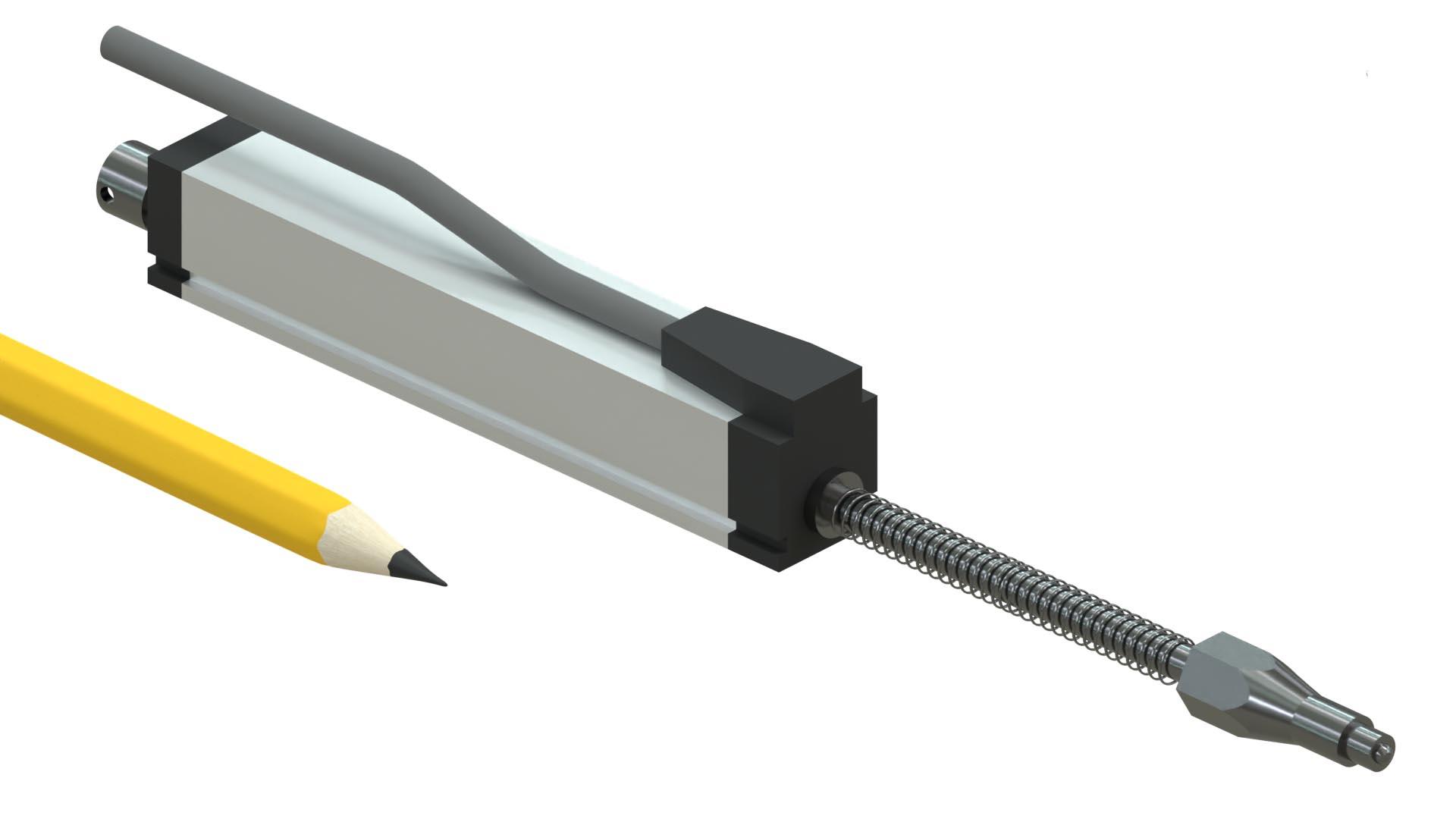

• Spring Loaded Linear Potentiometer

• Stroke lengths available from 10 to 100 mm (0.4 to to 4 inches)

• Includes mounting brackets

• Environmental rating of IP61 (Dust tight, Water resistant)

• Compact Size, housing is only 18 mm x 18 mm

LPPS-SL series Spring Loaded Linear Potentiometer Travel Sensors are used to monitor and track the linear motion or position of a target. These compact sensors are ideal for use in gauging applications including laboratory, automotive, industrial, motion control, medical, and aerospace.

Resistive potentiometric element is made from conductive plastic. Output is ratiometric; from 0% to 100% of excitation voltage.

The LPPS-SL series sensor is made from industrial duty materials for resistance to dust, temperature, shock, and vibration.

Options:

TECHNICAL SPECIFICATIONS

Stroke Lengths: | 0.4" (10mm), 1" (25mm), 2" (50mm) 3" (75mm), 4" (100mm) |

Mechanical Stroke Length: | Stroke Length + 0.12" (3 mm) |

Non-Linearity (BFSL method): | </= +/- 2.5% of full stroke |

Resolution: | Infinite |

Repeatability: | 0.0004" (0.01 mm) |

Element Type: | Conductive plastic |

Output: | 0 to 100% of excitation voltage |

Element Resistance: | 1.0, 3.0, and 5.0K ohm (+/- 20%) |

Maximum Excitation Voltage: | 36 VDC |

Current Draw: | ~10 mA (nominal) |

Output Cable: | 3 conductor, 24 AWG, braided shield, PVC jacket, 3 foot long |

Operating Temperature Range: | -40 to +203°F (-40 to +95°C) |

Thermal Coefficient of Sensitivity: | <0.03%/°C nominal |

Humidity: | 95% Max. RH (non-condensing) |

Liquid & Dust Protection: | IP61 |

Shock Rating: | 50g (single hit), IEC68-2-29:1968 |

Vibration Rating: | 20g, IEC68-2-6:1982 |

Housing Dimension (O.D): | 0.70" x 0.70" (18 mm x 18 mm) |

DOCUMENTS & DOWNLOADS

VIDEOS

PRODUCT NUMBERS

LPPS-SL Series Spring Loaded Linear Potentiometer Position Sensor

Product Description

The LPPS-SL Series Spring Loaded Linear Potentiometer Position Sensor delivers precise measurement capabilities in a compact, self-contained package ideal for gauging and direct contact measurement applications. Featuring an integrated spring-loaded plunger mechanism, this versatile sensor provides consistent contact force against the target surface while delivering accurate position feedback. With its space-efficient 18mm x 18mm housing and included mounting brackets, the LPPS-SL combines installation convenience with exceptional performance for applications ranging from quality control systems to automated inspection equipment.

Available in stroke lengths from 10 to 100 mm (0.4 to 4 inches)

Integrated spring mechanism for consistent contact measurement

Includes mounting brackets for simplified installation

Ratiometric output for accurate measurement

IP61 rated for dust-tight and water-resistant operation

Ultra-compact 18mm x 18mm housing for space-efficient integration

The LPPS-SL is perfectly suited for dimensional gauging, part presence verification, profile measurement, and position monitoring applications where direct contact measurement is required.

Industrial Performance

Precision Gauging Design

The LPPS-SL Spring Loaded Linear Potentiometer is specifically engineered for applications requiring direct contact measurement with consistent contact force. The integrated spring mechanism ensures reliable connection with the target surface while compensating for minor variations in positioning and alignment. This self-contained design eliminates the need for external springs or actuators, simplifying installation while improving measurement repeatability.

Compact Measurement Technology

Despite its small footprint, the LPPS-SL utilizes a high-quality conductive plastic resistive element to provide consistent, reliable position feedback. Its ratiometric output (0% to 100% of excitation voltage) ensures accurate measurements across the entire stroke range. This precision, combined with the compact 18mm x 18mm profile, makes the LPPS-SL ideal for applications where space is limited but measurement accuracy remains critical.

Applications

Dimensional Inspection

In manufacturing quality control, the LPPS-SL provides direct measurement of part dimensions, enabling real-time verification against specifications. The spring-loaded design allows for consistent measurements even with slight variations in part positioning.

Surface Profile Measurement

For surface profile analysis, the spring-loaded plunger maintains constant contact with irregular surfaces, providing accurate dimensional data for quality assessment and process control.

Laboratory Instrumentation

The LPPS-SL delivers exceptional performance in laboratory settings:

Research Equipment

In research applications, the compact size and included mounting brackets allow for easy integration into experimental apparatus where space is limited but measurement precision is essential.

Scientific Apparatus

For scientific instruments requiring position feedback, the LPPS-SL's spring-loaded design provides reliable data acquisition with minimal setup complexity.

Automated Manufacturing

The precision and compact design of the LPPS-SL make it ideal for manufacturing applications:

Assembly Verification

The sensor can verify proper assembly by directly measuring component positions or alignments in automated production systems.

Process Monitoring

For manufacturing processes requiring continuous position monitoring, the LPPS-SL provides real-time feedback for improved control and diagnostics.

Medical Equipment

The compact size and precise measurement capabilities of the LPPS-SL suit it for medical applications:

Diagnostic Devices

In medical diagnostic equipment, the sensor can monitor critical positions and movements with minimal space requirements.

Laboratory Analysis

For medical laboratory equipment, the LPPS-SL's compact package and direct measurement capability simplify the monitoring of mechanical positions in analytical instruments.

Installation and Integration

Mounting Options

The LPPS-SL includes versatile mounting brackets for simple installation:

Direct attachment to measurement fixtures

Integration with gauging systems

Flexible positioning for optimal measurement access

Secure mounting in space-constrained assemblies

Electrical Specifications

The LPPS-SL features straightforward electrical connections:

Ratiometric output proportional to position (0-100% of excitation voltage)

Conductive plastic resistive element for extended operational life

Simple three-wire configuration

Compatible with standard industrial controllers and data acquisition systems

System Integration

For maximum performance, the LPPS-SL can be integrated with:

Quality control monitoring systems

Data acquisition equipment

Statistical process control (SPC) software

Automated inspection systems

Custom measurement solutions

Durability Features

The LPPS-SL is built to withstand challenging measurement environments:

Industrial-grade construction for extended operational life

IP61 environmental rating for protection against dust and water

Materials resistant to temperature fluctuations

Robust design to withstand vibration and shock

Engineered for consistent performance in industrial settings

Customization Options

The LPPS-SL can be tailored to meet specific application requirements:

Various stroke lengths from 10mm to 100mm

Custom spring force options for specialized applications

Modified mounting configurations

Special cable specifications including length and termination

Enhanced environmental protection for demanding environments

Construction Quality

The LPPS-SL is manufactured with precision and durability as core design principles. Its compact yet robust housing provides excellent protection for the internal components, while the IP61 environmental rating ensures resistance to dust and water intrusion. This thoughtful construction ensures reliable operation even in challenging industrial and laboratory environments.

Compact Direct-Contact Position Sensing

The LPPS-SL Series Spring Loaded Linear Potentiometer Position Sensor represents an ideal solution for applications requiring direct contact measurement in a compact, self-contained package. Its integrated spring mechanism and space-efficient design make it particularly suitable for demanding applications across quality control, laboratory, manufacturing, and medical sectors.

By incorporating this sensor into your systems, you benefit from:

Integrated spring-loaded design for consistent contact measurement

Space-efficient 18mm x 18mm housing for installations with limited space

Included mounting brackets for simplified installation

Precise position measurement with reliable ratiometric output

Durable construction for consistent long-term operation

Versatility across multiple application domains

For engineers and designers seeking compact, reliable direct-contact position feedback solutions, the LPPS-SL offers proven technology with the convenience and measurement capability to meet modern application requirements.