OVERVIEW

Features

• Spring loaded AC LVDT probe

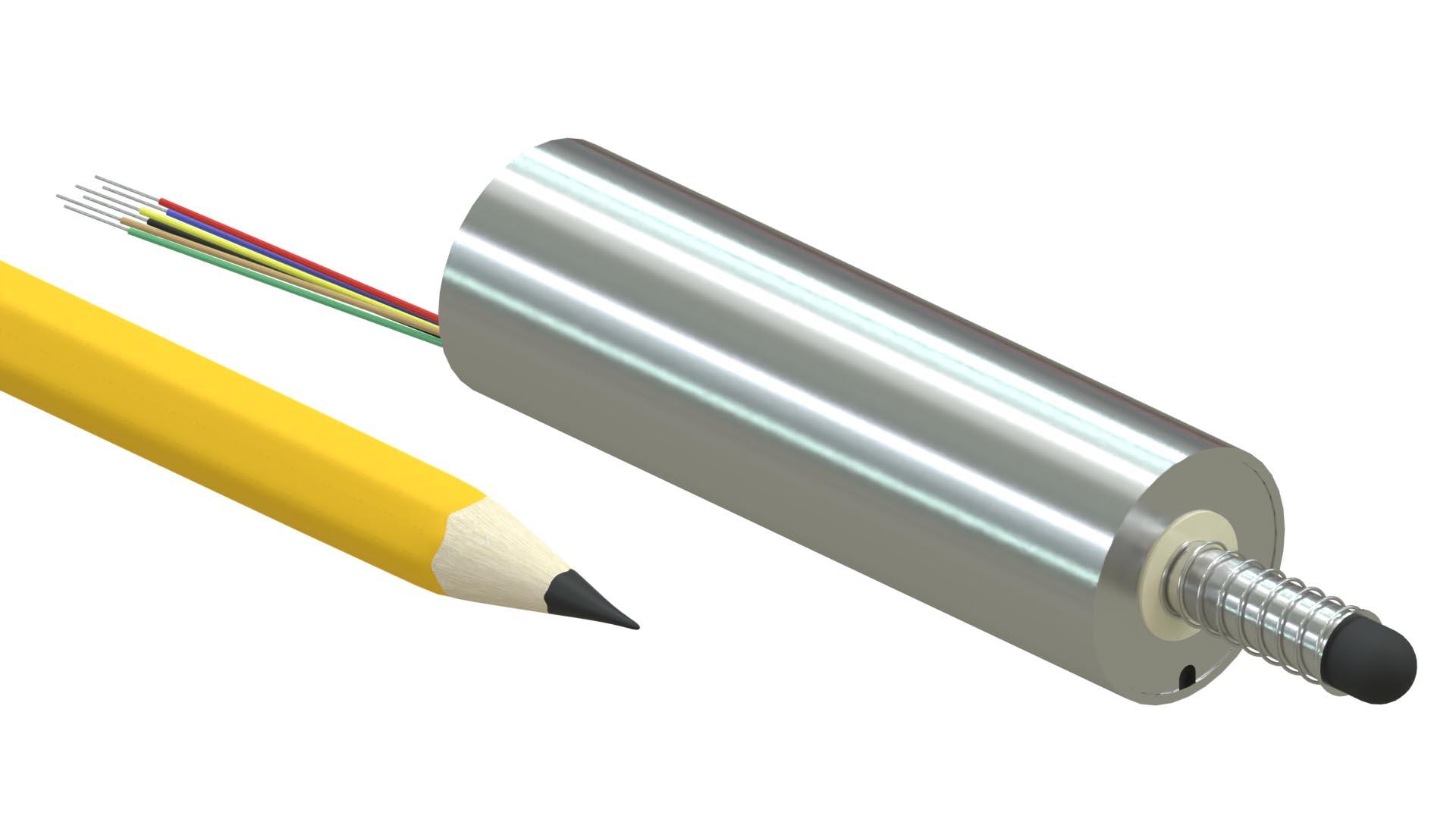

• Smooth 0.750" (19 mm) O.D. stainless steel housing

• Stroke lengths from ±0.100 to ± 0.300 inches (2.5mm to 7.5mm)

• Non-linearity better than ±0.5% of FS

• Sealed to IP61

MADE IN THE USA

The HGSI GT-750-A series of short range spring loaded position sensors were developed for cost sensitive applications requiring LVDT reliability and performance. Available in ranges of ±0.10 inches to ±0.30 inches, these sensors offer the excellent measurement capabilities of an LVDT at very economical prices.

The sensor shaft is spring loaded and guided by a nylon sleeve bearings. These sensors are constructed of stainless steel and are resistant to dust, temperature, shock, and vibration.

The GT-750-A series will operate with most any conventional differential input AC LVDT signal conditioner, but operation with ratiometric signal conditioning is not recommended. HGSI offers a full line of compatible AC LVDT signal conditioners. Please contact us for a recommendation.

Part Numbers

GT-750-A-100 Travel: +/- 0.100 inch (+/- 2.5 mm)

GT-750-A-200 Travel: +/- 0.200 inch (+/- 5.0 mm)

GT-750-A-300 Travel: +/- 0.300 inch (+/- 7.5 mm)

Options:

TECHNICAL SPECIFICATIONS

Input Voltage: | 3 Vrms (nominal) |

Input Frequency: | 3 kHz (nominal) |

Linearity Error: | ≤ ± 0.5% of reading typical |

Repeatability: | 0.01% of FS |

Operating Temperature: | -30 to 105°C (-20 to 220°F) |

Thermal Coefficient: | < -0.03%/°C of FS |

Housing: | Stainless Steel |

Contact Tip: | AGD #9 hardened tool steel, chrome plated, M2,5 male thread interchangeable |

Sleeve Bearings: | Nylon |

Integral Cable: | 1 foot (0.3 m) long, FEP Teflon outer jacket |

Life Expectancy: | > 10 million cycles |

Shock Rating: | 1000g, 11 mS |

Vibration Rating: | 20 g to 2 kHz |

IP Rating: | IEC IP65 |

DOCUMENTS & DOWNLOADS

VIDEOS

PRODUCT NUMBERS

Product Overview

The GT-750-A Series Spring-Loaded AC LVDT from Harold G. Schaevitz Industries offers the proven performance and reliability of LVDT technology in a compact, economical package. Designed for short-range measurements, this sensor is ideal for cost-sensitive applications that still demand accuracy, repeatability, and durability.

With stroke lengths ranging from ±0.100 to ±0.300 inches (2.5 mm to 7.5 mm), a 0.750" (19 mm) diameter stainless steel body, and a non-linearity of ±0.5% of full scale, the GT-750-A is a versatile choice for dimensional gauging, inspection, and test stand use in both industrial and laboratory environments.

Cost-Effective Precision

The GT-750-A delivers accurate linear displacement measurements at an economical price point, making it an excellent alternative to more expensive solutions when space and budget are limited. Its external spring-loaded mechanism ensures consistent contact with the target surface, while the compact design allows for easy integration into a variety of applications.

This sensor uses traditional AC LVDT technology, offering contactless, frictionless measurement and excellent repeatability with minimal drift over time.

Rugged and Reliable Design

Constructed from stainless steel with a sealed IP61 housing, the GT-750-A offers solid protection against dust, shock, and vibration. The nylon sleeve bearings provide stable axial guidance for the probe shaft while helping to minimize cost for budget-conscious installations.

This combination of rugged construction and cost-effective design makes the GT-750-A well-suited for both industrial and research environments where high accuracy is required, but environmental conditions are relatively controlled.

Applications

Laboratory and R&D

In research and development labs, the GT-750-A provides high-resolution position feedback in compact setups, including materials testing rigs and dimensional metrology systems.

Industrial Gauging

Ideal for integration into quality control systems, the GT-750-A delivers fast, reliable data in automated gauging stands and other dimensional inspection tools.

Factory Automation

In automated production lines, the GT-750-A tracks linear displacement for machine positioning, component alignment, and contact measurement in compact mechanical assemblies.

Light-Duty Measurement Tasks

For non-critical environments where extreme sealing and ruggedization aren’t necessary, the GT-750-A provides an affordable yet dependable solution for short-range linear sensing.

System Compatibility

The GT-750-A is designed to operate with most standard differential-input AC LVDT signal conditioners. Harold G. Schaevitz Industries offers a variety of compatible signal conditioning modules—contact our team for recommendations tailored to your application.

Why Choose the GT-750-A?

Economical solution for short-range precision measurement

Reliable AC LVDT technology with contactless core movement

Spring-loaded design for consistent target contact

Compact and easy to install in tight spaces

Stainless steel construction, long service life

Made in the USA with engineering support available

Affordable Accuracy for Short-Range Sensing

The GT-750-A Series Spring-Loaded AC LVDT is the ideal solution for engineers and mechanical system designers seeking high-accuracy displacement sensing in compact, budget-conscious applications. With its spring-loaded probe, rugged stainless steel body, and AC LVDT reliability, the GT-750-A delivers exceptional performance for its size and price.

Whether you're outfitting a gauging station, automating a quality control process, or developing a new test system, the GT-750-A offers the precision, value, and durability to get the job done.

Need help selecting the right LVDT for your system?

Reach out to our experienced application engineers today for any questions about your specific application.