LVDT Technology Overview

Linear Variable Differential Transformer (LVDT) position sensors are electromechanical devices that convert the linear motion of a mechanically coupled object into a corresponding electrical signal. LVDT sensors are highly precise and can accurately measure linear motion, even sensing movements as small as a few millionths of an inch.

LVDT Coil Assembly

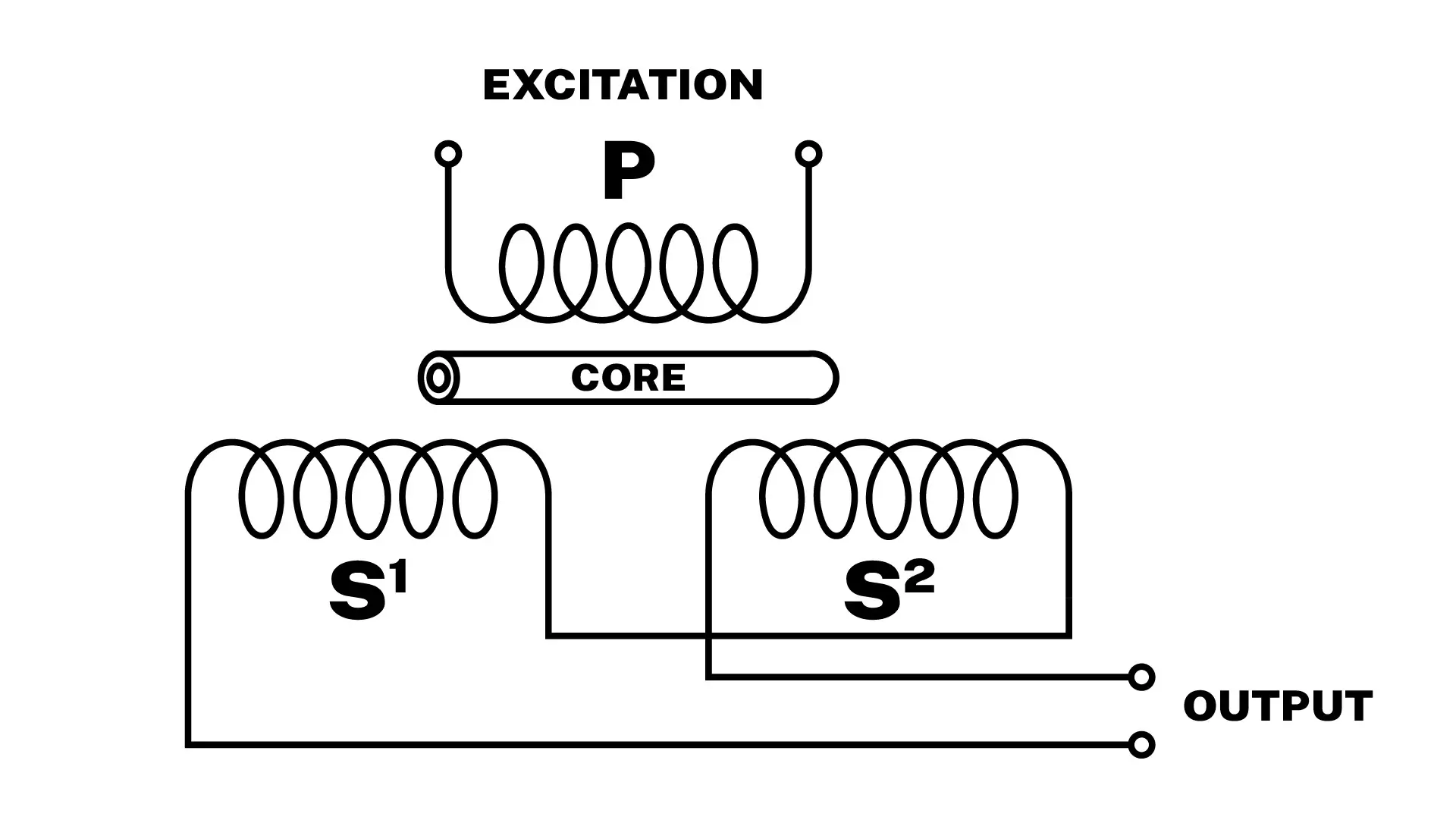

The diagram below shows the internal structure of a typical LVDT. Being an electrical transformer, it has a primary winding typically located symmetrically between two identically-wound secondary coils, which are all wound on a tube of a thermally-stable, glass-filled polymer. It is then encapsulated against moisture, wrapped with a thin high-permeability magnetic shield, and potted into a tubular stainless steel housing. This assembly is normally the stationary or fixed element of an LVDT position sensor

.jpg)

LVDT Core

The moving element of an LVDT is a separate cylindrical armature of magnetically permeable material called the core. The core can move freely back and forth inside the bore of the coil assembly, and it is mechanically connected to the object whose position is being measured. Because the hollow bore of the coil assembly has a reasonably large radial clearance, no physical contact between the core and the coil assembly is necessary. This makes frictionless position sensing operation possible in some applications.

LVDT Operation Explained

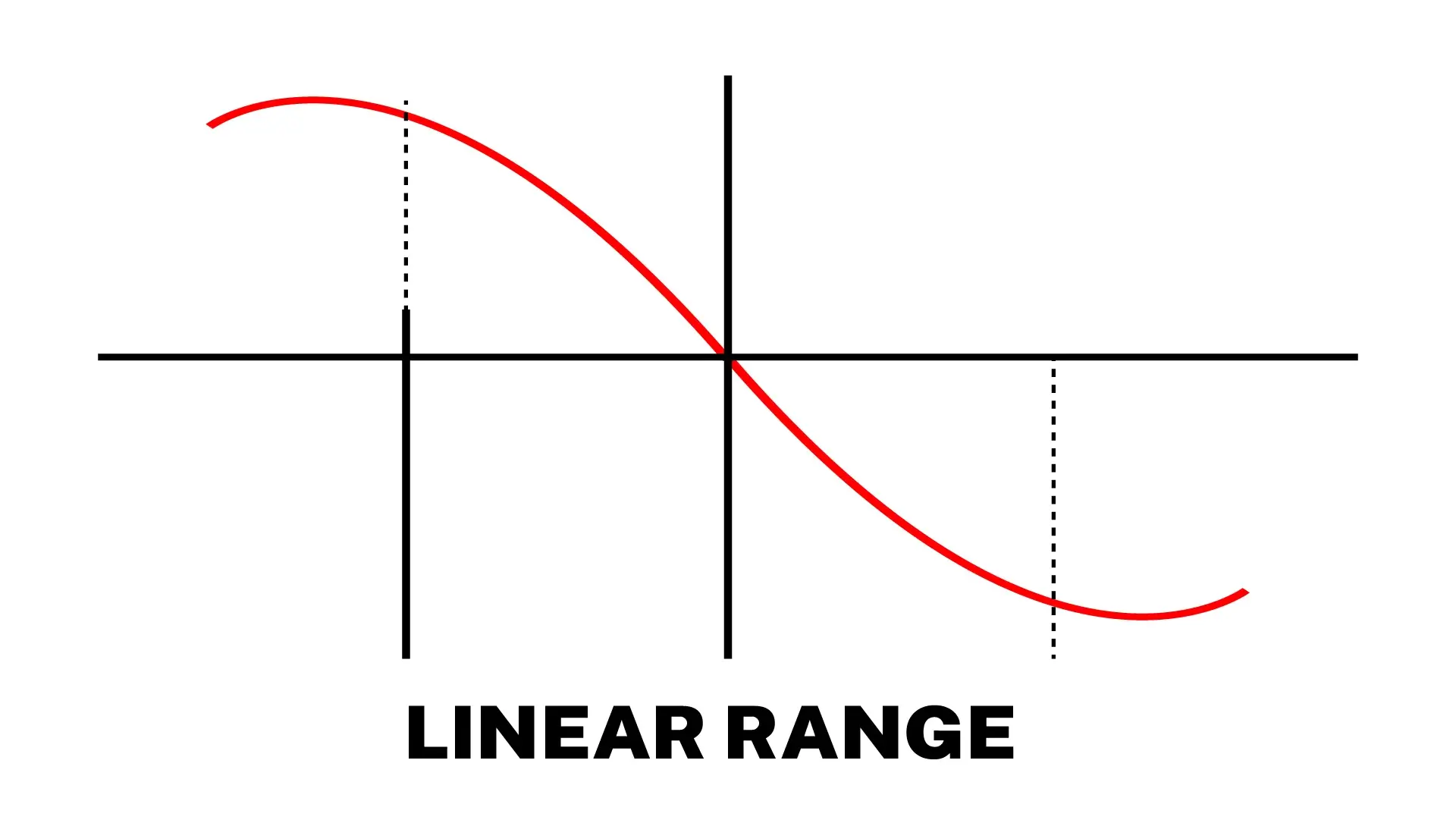

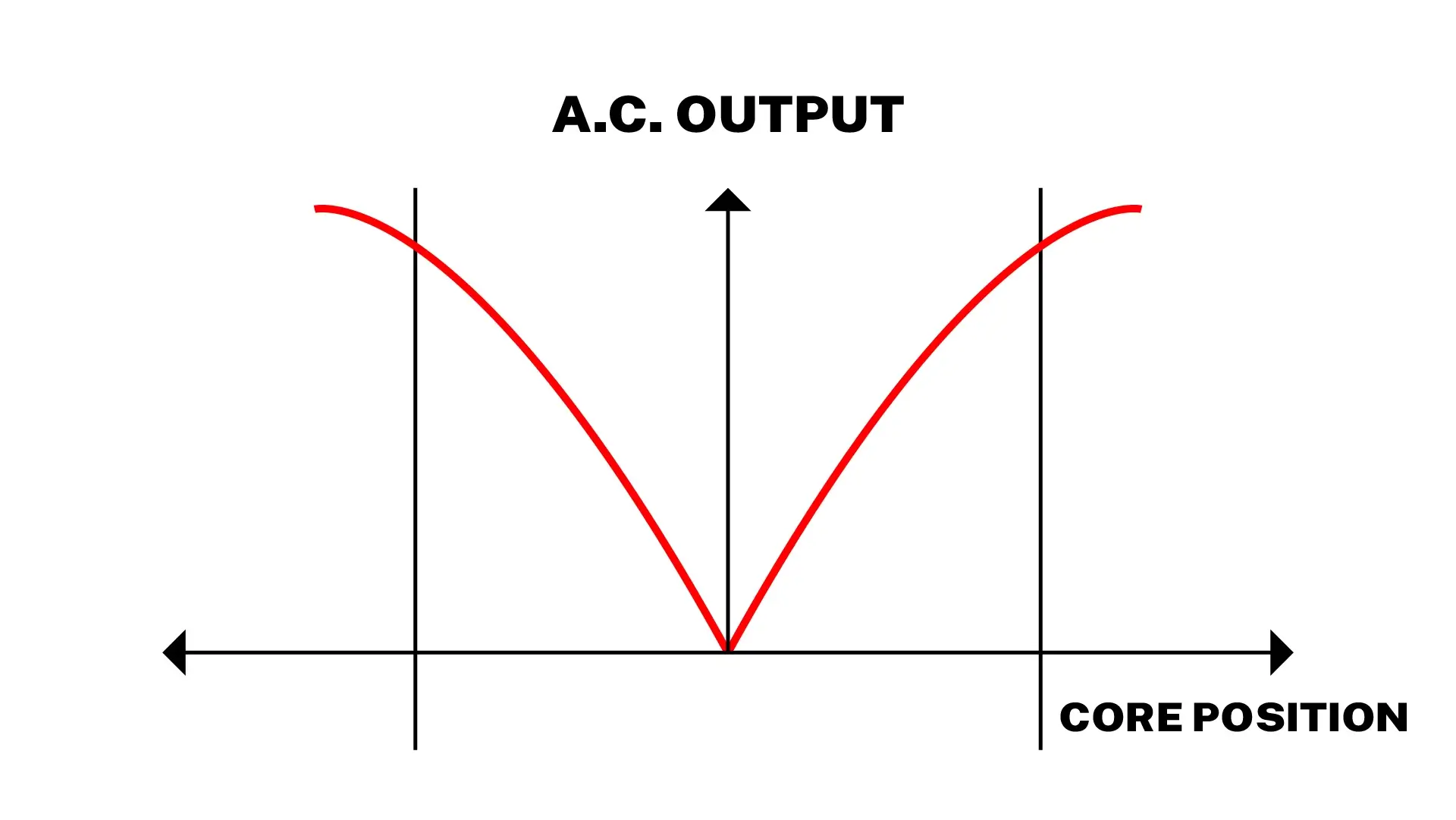

In operation, an LVDT (Linear Variable Differential Transformer) is energized by an alternating current of a specified amplitude and frequency, referred to as the primary excitation. The LVDT produces an electrical output signal in the form of an AC voltage between its two differentially-connected secondary windings. This voltage changes according to the axial position of the core inside the LVDT coil assembly. As a result, when the object coupled to the LVDT core moves, its position determines a corresponding AC output voltage, which is usually converted into a high-level DC voltage or current using specialized signal conditioning electronics.

LVDT Applications

LVDT (Linear Variable Differential Transformer) sensors are widely used in various industries and applications due to their precision, reliability, and durability. Some common applications for LVDT sensors include:

- Displacement and Position Measurement: LVDT sensors are frequently used to measure linear displacement or position in machines, equipment, and structures. They can provide accurate and repeatable measurements of movement or position, making them suitable for dimensional gaging and QA part inspection, machine tool positioning, and electrohydraulic valve spool position feedback.

- Automation and Robotics: LVDT sensors are integrated into automation systems and robots to provide feedback on the position of robotic arms, grippers, and other moving parts. This enables precise control and enhances the safety and efficiency of automated processes

- Material Testing: In material testing applications, LVDT sensors measure strain and deformation in materials subjected to mechanical stress or force. They play a crucial role in structural and mechanical testing, ensuring the integrity and quality of construction materials and high-reliability mechanical parts.

- Aerospace and Aviation: LVDT position sensors are utilized in aerospace and aviation for a variety of positioning applications, such as control surface position monitoring, landing gear position sensing, and turbojet engine vane position feedback.

- Civil Engineering: In civil engineering projects, LVDT sensors are employed to monitor the structural health of buildings, bridges, and other infrastructure. They detect changes in structural position or deformation, providing early warning of potential structural issues.

- Factory Automation: LVDT sensors find applications in factory automation for measuring the position of conveyor belts, robotic arms, and other industrial equipment, ensuring precise control of movement.

- Power Generation: In power generation plants, LVDT sensors are used to monitor the position of steam valves, dampers, and other critical components. This helps optimize the operation of power generation plant systems, enhances uptime reliability, and improves plant worker safety.

- Automotive Industry: LVDT sensors are used in the automotive industry for tasks such as suspension system monitoring, engine component position sensing, and gearbox position feedback.

- Medical Devices: LVDT sensors are employed in various medical devices and equipment, including patient positioning systems, robotic surgical tools, and medical imaging camera positioning.

- Research and Development: LVDT sensors are utilized in research and development laboratories for a wide variety of experiments and projects that require precise displacement and/or position measurement.

Overall, the versatility, durability, and accuracy of LVDT sensors make them suitable for a very wide range of position measurement applications across many different industries.

Optimize your industrial application with Harold G Schaevitz Industries LVDTs today!

Harold G Schaevitz Industries (HGSI) offers a wide range of LVDT position sensors, instrumentation, and accessories designed to meet the needs of your demanding industrial application.

Our experienced application engineers are standing by to help you find an appropriate solution for your position measurement problem. For additional pricing and technical questions, please contact us now!