Linear Variable Differential Transformers (LVDTs) are known for precision, durability, and reliability in many industrial and test applications. To apply them correctly, you need to understand the difference between mechanical stroke, electrical (calibrated) stroke, pretravel, and overtravel. These terms define the usable travel of the sensor and the safe margins at each end of that travel

Key terms

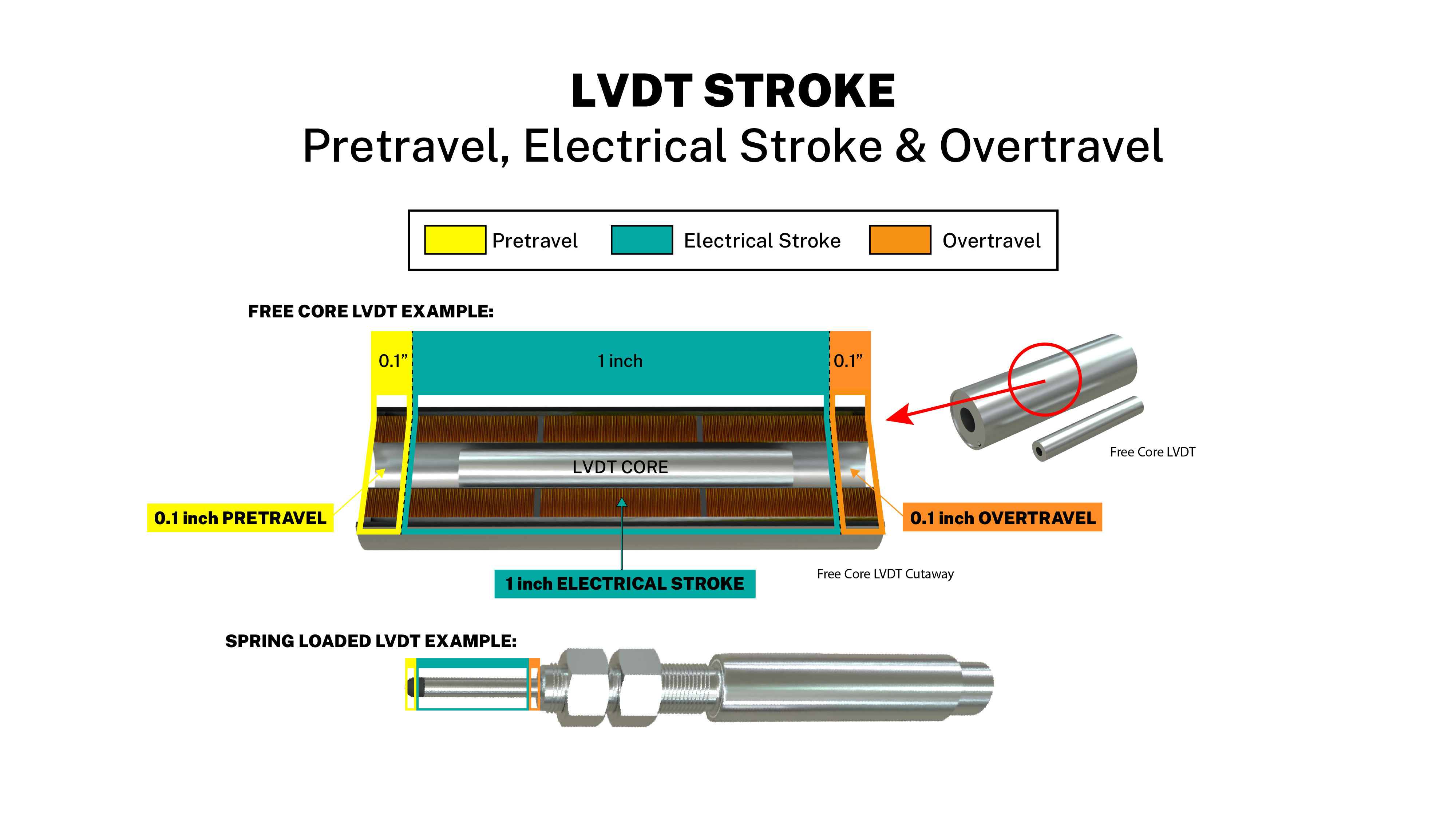

- Mechanical stroke — the total physical travel the core can move inside the sensor bore.

- Electrical (calibrated) stroke — the portion of the mechanical stroke over which the LVDT provides its specified, linear, calibrated output. This is the range you use for measurements.

- Pretravel — the small mechanical margin before the electrical stroke begins. Pretravel gives a tolerance at the start of motion so the core does not immediately enter the calibrated region from a potentially misaligned or slightly over-inserted starting position.

- Overtravel — the mechanical margin after the electrical stroke ends. Overtravel provides a safety buffer at the far end of travel to protect the sensor if the mechanism moves slightly beyond the calibrated range.

How they fit together

A sensor’s total mechanical stroke is the sum of pretravel + electrical stroke + overtravel.

Example:

Total mechanical stroke = 1.2 in.

Pretravel = 0.1 in. (before the electrical range)

Electrical (calibrated) stroke = 1.0 in.

Overtravel = 0.1 in. (after the electrical range)

In this example the core can move 1.2 inches physically; only the central 1.0 inch is guaranteed to produce calibrated, linear output. The 0.1-inch pretravel and 0.1-inch overtravel are safety/tolerance margins and are not part of the calibrated measurement range.

Why this distinction matters

- Accuracy: Only the electrical stroke should be used for position measurement. Readings taken in pretravel or overtravel are outside the calibrated range and can be non-linear or unreliable.

- Installation: Understanding pretravel and overtravel helps set up mechanical limits and stops so the core enters and remains within the electrical stroke during normal operation.

- Damage prevention: Pretravel and overtravel are a protective allowance, not a zone for regular use.

Best practices

- Consult the datasheet. Always use the manufacturer’s specs for pretravel, electrical stroke, and overtravel for your specific model. Values vary by design.

- Design mechanical stops. Add stops or limiters in the mechanical system so normal motion stays inside the electrical stroke. Use the overtravel margin only for infrequent overshoot protection.

- Account for mounting tolerances. Use pretravel as a buffer during assembly so minor positioning errors don’t force the core outside safe limits.

- Avoid using the sensor as a hard stop. Rely on dedicated mechanical stops to absorb impact and protect the LVDT.

- Recalibrate after changes. If you replace or reposition the core or change mounting geometry, re-check calibration and alignment per the vendor’s instructions.

Summary

Pretravel and overtravel are safety and tolerance margins that bracket the electrical (calibrated) stroke:

- Pretravel = margin before the electrical stroke begins.

- Electrical stroke = the calibrated range for accurate measurements.

- Overtravel = margin after the electrical stroke ends.

Understanding and designing for these zones ensures accurate readings, prevents damage, and extends the life of your LVDT. If you need help interpreting a datasheet or choosing an LVDT with the right travel margins for your application, contact us now!