Harold G. Schaevitz Industries LLC’s LVIT Linear Position Sensors offer SenSet® Field Programmability. SenSet® allows the installer to very simply and quickly exactly match the full scale electrical output of a sensor to the actual mechanical movement range of the device in which the sensor is installed.

Please note that your LVIT Sensor was calibrated at the factory to a specified measuring range. You may choose to retain this calibration if it fits your purpose, or you may choose to re-calibrate your sensor using the SenSet® feature if you desire a more precise match of the sensor’s electrical output to your mechanical device’s range of movement. This activity is usually referred to as a field calibration.

Please note that your LVIT Sensor was calibrated at the factory to a specified measuring range. You may choose to retain this calibration if it fits your purpose, or you may choose to re-calibrate your sensor using the SenSet® feature if you desire a more precise match of the sensor’s electrical output to your mechanical device’s range of movement. This activity is usually referred to as a field calibration.

To proceed with a SenSet® based field calibration, follow these instructions:

- Install the sensor into your mechanical device, leaving the sensor’s I/O unconnected.

- Connect the black wire or ground terminal to the power ground (-), and then connect the correct DC power input plus (+) to the sensor via the red wire or power (+) terminal.

- To begin the SenSet® process for voltage output, connect a DC voltmeter having the appropriate range with its plus (+) lead connected to the green wire or the output terminal and its minus (-) lead connected to the black wire or the power ground terminal.

- To begin the SenSet® process for current loop output, connect a DC milliammeter having the appropriate range with the its plus (+) lead connected to the green wire or the output terminal, and its minus (-) lead connected to the loop load resistor, typically 250 or 500 Ohms. Connect the other end of the loop load resistor to the black wire or the power ground terminal.

- Extend your mechanical device to its maximum range of motion, then connect the white (cal) wire or cal terminal to the black wire or ground terminal for 2-3 seconds.

- Fully retract the mechanical device to its zero (start) position, then connect the white (cal) wire or the cal terminal to the black wire or ground terminal for 2-3 seconds.

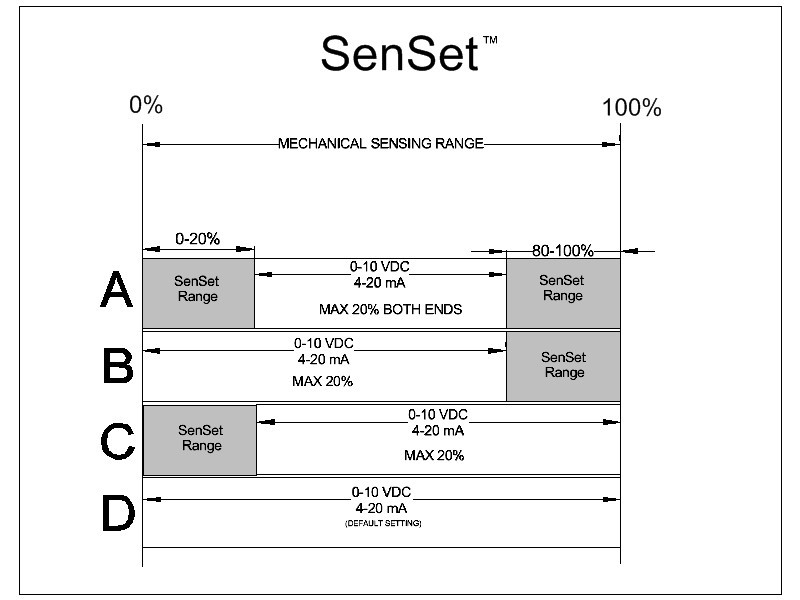

- The sensor’s output is now calibrated to the end points of your mechanical device's range of motion. The SenSet® procedure can be redone without limit, but its operational range is limited to 20% of specified full range, both at zero and at full range. (0 to 20% around zero, and 80 to 100% around full range). Note that both ends of the sensor's range must be calibrated using the SenSet™ procedure for the process to take effect.

- When the SenSet® process is completed, disconnect the voltmeter, or, in the case of current loop output, disconnect the milliammeter and reconnect the loop load to the green wire or the output terminal. If using a leaded or cable output sensor, trim and insulate the end of the white (cal) wire to avoid an inadvertent recalibration.

To restore the LVIT to its factory calibration, connect the white wire to the power supply ground for 30 seconds. SenSet is resettable and can be done at any time. At no point should the white wire come into contact with the positive side of the power supply.

Below is an example of how the SenSet® feature can be used to match various mechanical ranges to the desired electrical output. The maximum range is 20% from both 0% and 100% positions (see figure 1).

SenSet® Field Programmability Video Instructions:

Additional pricing or technical questions?

Categories

Page Categories