OVERVIEW

• Spring loaded probe

• AC LVDT

• 0.315" (8mm) or 0.375" (9.5mm) O.D. size body

• Stroke lengths from ± 0.020 to ± 0.200 inches (±0.5mm to ±5mm)

• Non-Linearity better than ± 0.5% of FS

• Stainless steel housing sealed to IP65

• Applications: Laboratory R&D Materials Testing, Industrial Gauging Test Stands, Factory Automation

MADE IN THE USA

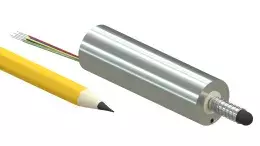

The HGSI GB series Spring Loaded AC Linear Variable Differential Transformer (LVDT) gauging probes are pencil-type gauging probes used for ultra-precise dimensional measurement. These spring-loaded sensors are ideal for use in industrial and laboratory applications including QC, SPC, metrology, & dimensional gauging.

The sensor shaft is spring loaded and guided by a precision linear ball bearing assembly. The non-rotating probe shaft minimizes radial play and effects of side loading. These sensors are constructed of stainless steel and are resistant to dust, temperature, shock, and vibration.

The GB series will operate with most any conventional differential input AC LVDT signal conditioner, but operation with ratiometric signal conditioning is not recommended. HGSI offers a full line of compatible AC LVDT signal conditioners. Please contact us for a recommendation.

Options:

TECHNICAL SPECIFICATIONS

Input Voltage: | 3 Vrms (nominal) |

Input Frequency: | 5 kHz (nominal) |

Linearity Error: | ≤ ± 0.5% of reading typical |

Repeatability: | ≤ 0.000006 inches (0.15 μm) |

Operating Temperature: | 5 to 80°C (40 to 176°F) |

Thermal Coefficient: | < -0.01%/°C of FS |

Housing: | Stainless steel |

Contact Tip: | AGD #9 hardened tool steel, chrome plated, M2.5 x 0.45 male thread, interchangeable |

Bellows: | Fluoroelastomer |

Integral Cable: | 6.5 foot (2 m) long, 28 AWG stranded conductors, foil shielded, with drain wire, PUR polyurethane outer jacket |

Life Expectancy: | > 10 million cycles |

Shock Rating: | 1000g, 11 mS |

Vibration Rating: | 20 g to 2 kHz |

IP Rating: | IEC IP65 |

Country of Manufacture: | USA |

DOCUMENTS & DOWNLOADS

VIDEOS

PRODUCT NUMBERS

GB Series Spring-Loaded AC LVDT Gauging Probe

Product Overview

The GB Series Spring-Loaded AC LVDT Gauging Probe from Harold G. Schaevitz Industries is a precision-engineered solution for ultra-accurate linear displacement measurement. Designed for laboratory R&D, quality control, and industrial gauging applications, these compact and rugged sensors offer superior performance in tight spaces and demanding environments.

With body diameters of 0.315" (8 mm) or 0.375" (9.5 mm) and full-scale stroke lengths ranging from ±0.020 to ±0.200 inches (±0.5 mm to ±5 mm), the GB Series delivers highly repeatable and reliable results. Built from stainless steel and sealed to IP65, these gauging probes are ideally suited for environments where precision and durability are required.

Precision Performance in a Compact Package

The GB Series is a true pencil-style gauging probe, offering a space-efficient form factor ideal for installation in multi-point gauging fixtures, automated measurement setups, and confined mechanical environments. Despite its compact size, the GB Series offers excellent mechanical stability, precise measurement repeatability, and excellent noise immunity when used with a compatible signal conditioner.

The non-rotating shaft and linear guided bearings ensures that measurements are not affected by lateral forces or twisting, while the spring-loaded mechanism allows for continuous and consistent contact with the surface being measured.

High Accuracy and Linearity

With a non-linearity of better than ±0.5% of full scale and repeatability of 40 millionths of an inch, the GB Series delivers dependable measurement accuracy for precision applications. This level of performance is ideal for:

High-resolution material testing

Statistical process control (SPC)

Dimensional gauging in automated or manual setups

Quality assurance stations in production environments

Rugged Construction

The GB Series is constructed from stainless steel to provide long-lasting durability in both laboratory and factory settings. The housing is sealed to IP65, offering protection from dust and moisture ingress during operation. The internal precision bearing assembly ensures that shaft movement remains smooth and true, even during high cycle testing or in the presence of environmental vibration.

Applications

Laboratory and R&D Testing

Ideal for materials testing labs and dimensional metrology systems where precise displacement readings are required across short stroke ranges.

Factory Automation

Integrated into industrial test stands and automated gauging systems to ensure consistent product quality and dimensional control in real time.

Quality Control & Inspection

Used in QC stations for manual and automatic inspection, helping manufacturers maintain tolerances and improve production efficiency.

Metrology & SPC Systems

Supports the requirements of statistical process control by delivering accurate, repeatable measurements critical for high-mix and high-volume environments.

System Integration and Compatibility

The GB Series works with most conventional differential-input AC LVDT signal conditioners, offering a straightforward integration path into existing systems. HGSI offers a full range of AC signal conditioning solutions designed to complement these sensors—please contact us for recommendations.

Compact Precision for Dimensional Gauging

The GB Series Spring-Loaded AC LVDT Gauging Probe provides reliable, ultra-precise position feedback for high-performance measurement applications. Its rugged stainless steel construction, compact size, and accurate displacement measuring make it a standout solution for industrial gauging and R&D environments.

Why Choose the GB Series?

Compact, pencil-style body fits tight measurement locations

High linearity for accurate, highly repeatable results

Spring-loaded shaft with linear ball bearing guidance

Built tough for industrial and laboratory use

Compatible with most AC LVDT signal conditioners

Backed by HGSI’s engineering support and Made in the USA quality

Need help selecting the right stroke length or conditioner for your setup?

Contact our application engineers today for personalized guidance and technical support.